Publications

14.04.2023

ZVEI-Show-Case PCF@ControlCabinet

Sustainability and the circular economy, including the associated decision-making criteria, are already a relevant topic today and are likely to become even more important in the near future. In this context, the topic of sustainability is fraught with great uncertainty, as the details and possible implementations in this area are not clear and can hardly be outlined. For example, the declaration of the Product Carbon Footprint (PCF) will become one of many new regulatory requirements of the European Union under the Ecodesign for Sustainable Products Regulation (ESPR) and the Green Deal. Following on from this, industry in all sectors will probably be required to provide certain product information in the form of a Digital Product Passport (DPP).

In the ZVEI-Show-Case "PCF@Control Cabinet", the ZVEI presents a flexible, efficient and future-proof concept for the technical implementation of a digital product passport and demonstrates its feasibility using a demonstrator. With the concept of the Digital Product Passport for Industry DPP4.0 concept, the industry is able to document and provide required product information. The DPP4.0 concept of the ZVEI is based on two essential pillars that were developed within the framework of the Industrie 4.0 initiative:

- the digital nameplate (DNP4.0) via IEC 61406 (Identification Link) and

- the Asset Administration Shell (AAS) according to IEC 63278 (under development)

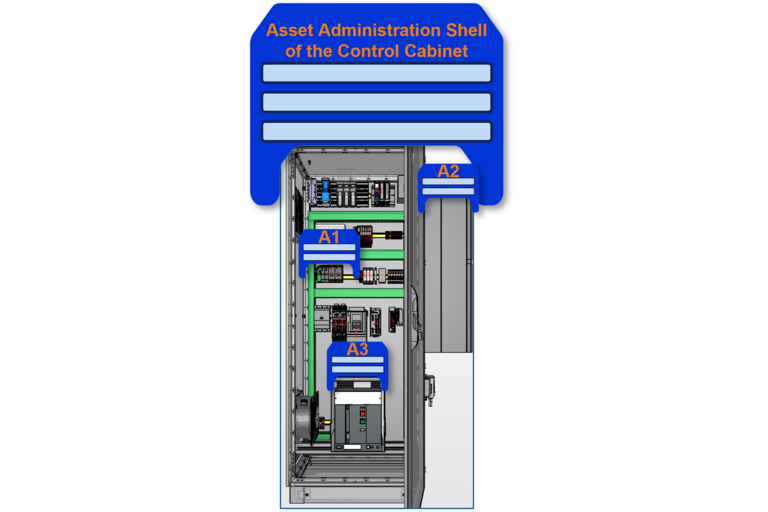

The basic idea of Industrie 4.0 is to link the OT and IT levels (operational technology and information technology). Each asset of the OT level (hardware and software) becomes an I4.0 component by linking it to the so-called Asset Administration Shell (AAS), which creates a general interoperability between all I4.0 components and connects the I4.0 component with the IOT world in a plug-and-play manner.

The AAS represents a framework format for describing the assets in a standardised and semantically unambiguous form and thus functions as a digital twin of the asset. The described characteristics and properties of the respective asset are summarised in the AAS in sub-models. As AAS is a key factor for the DPP4.0 concept, we are happy to work closely with the Industrial Digital Twin Association (IDTA). From this collaboration, the dedicated website for DPP4.0 was created: www.dpp40.eu

The first iteration of the ZVEI Show Case Demonstrator was already presented at Hannover Messe 2022. At Hannover Messe 2023, visitors will again be able to use the demonstrator to see how the product carbon footprint (PCF) of a control cabinet consisting of many different products from the participating companies is calculated automatically. Compared to last year, the number of participating companies has increased and new features in the area of security have been implemented.

The visitor learns how the sub-models for the Digital Nameplate DNP4.0 and the sub-model for the PCF value of the individual components are realised and how the PCF calculation of the overall system "control cabinet" was implemented.

This concept can be easily extended in the future by adding additional sub-models representing product information that needs to be documented under new and other regulatory requirements. It is a pattern that is easy to learn and therefore easy to repeat.

A remarkable team of ZVEI members has contributed to the project in order to show in an interdisciplinary and cross-company effort under the umbrella of ZVEI, how to prototypically combine different aspects that are important for the calculation of PCF values in order to meet regulatory, legal, economic and technical requirements.

The demonstrator at Hannover Messe 2023 is a version in which not all concepts have been implemented to the possible depth. Some questions are still open, but will be answered in the next steps. In particular, the stated values of the Product Carbon Footprints are to be regarded merely as examples for the technical proof of concept and, where applicable, as rough estimates - there is no claim to accuracy / correctness. In particular, the comparability of the product-specific product carbon footprints with each other is not given at this point in time.