09.12.2025

Interoperability as a success factor: The Asset Administration Shell in the context of data space (Whitepaper)

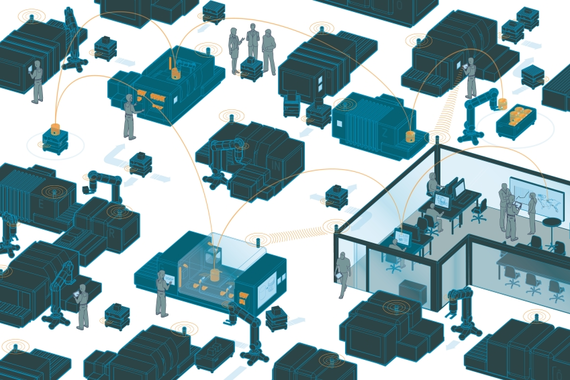

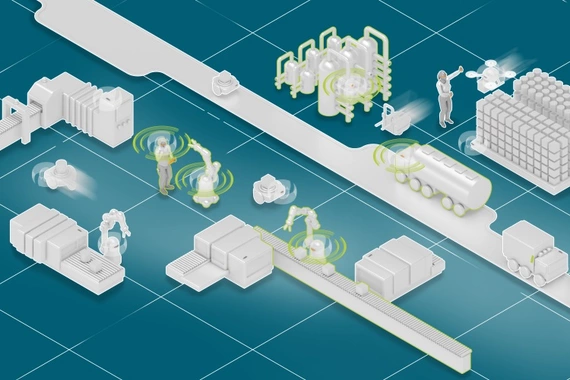

The industry faces challenges such as the growing regulation, geopolitical conditions, increasing global competition, and an acute…

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/d/6/csm_Image__19__8233a23957.jpg)