Publications

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/Presse_und_Medien/mediathek/YouTube-Vorschaubild/NOA-Namur-Open-Architecture-Connectivity.jpg)

19.06.2020

At the exhibition "Modular Production and NOA", manufacturers, users and module builders will jointly demonstrate how the flexibility of plants in the process industry can be significantly improved through module-based production with standardised interfaces. In addition, they will demonstrate an open automation architecture that enables the integration of IT components for Industrie 4.0 easily and without interference.

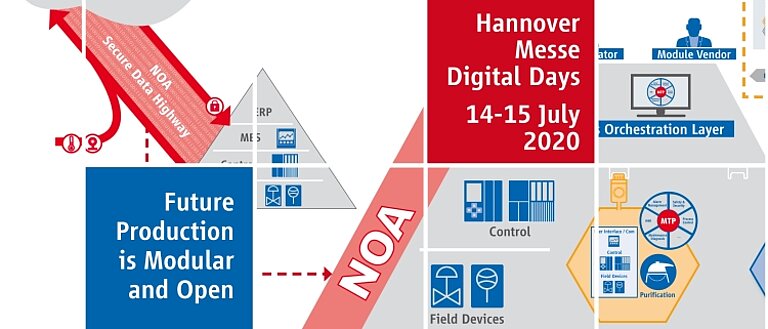

The exhibition of Modular Production is entitled "Process Industrie 4.0 - Future Production is Modular & Open" in 2020. Two technologies are brought together under this caption: On the one hand, the focus is on particularly fast and efficient engineering of modules - production units encapsulated in process and automation technology. Based on the Module-Type-Package concept (MTP), which gives the individual modules a digital description, the modules can then be interconnected flexibly and system-neutrally via the orchestration system. "In this way, process plants can be created and converted quickly, and the engineering effort is reduced considerably," says Axel Haller (ABB), Chairman of the ZVEI Modular Automation working group.

The other side is all about NAMUR Open Architecture (NOA). "For users in the process industry, there is great potential if plant data can be collected easily and quickly and evaluated across plants. This makes it easier, for example, to identify optimisation potential in the plants themselves or in the process," says Nils Weber, Managing Director of NAMUR. The classic automation pyramid is not dissolved, but rather expanded so that IT components can be easily integrated from the field level to corporate management. Field devices can then send specific data directly to the cloud via an additionally established communication channel. Plant safety and availability are not affected.

Partners of the special exhibition are Biophorum, NAMUR, Processnet - an initiative of Dechema, and VDI, VDMA and ZVEI.

Companies such as ABB, B&R, Copa-Data, Emerson, Endress+Hauser, Festo, HIMA, Pepperl + Fuchs, Phoenix Contact, Proleit, R.Stahl, Samson, Schneider Electric, Semodia, Siemens, Wago, Wika and Yokogawa are supporting the exhibition. Universities - for example, TU Dresden and Helmut Schmidt University of Hamburg - and a large number of users such as BASF, Bayer, CHT, Clariant, Covestro, Evonik, INVITE, Lanxess and Merck from the chemical and pharmaceutical industry in cooperation with module manufacturers are also taking part in the exhibition. Furthermore, system integrators such as SpiraTec and module builders such as Seepex are part of the project.

Further contacts:

James Colley, BioPhorum (EN)

Nils Weber, NAMUR / NOA

Alexander Möller, ProcessNet

Hauke Schlegel, VDMA